Project Site #3 : “The Innovative Lab of Architecture & Art” @ Qiong Kiln Heritage Site Park, Qionglai City, Sichuan Qiong Kiln is located along the South River in Qionglai City, Sichuan, It is the largest civil celadon kiln in Sichuan and the birthplace of Chinese painting porcelain. Qiong kiln site is a national key cultural relics protection units, has repeatedly been included in the national heritage protection list, and Sanxingdui, Jinsha sites tied for the three ancient archaeological sites in Sichuan. Accordance with the “Qiong Kiln site protection master plan” requirements, Qiong Kiln Heritage Site Park detailed planning is prepared. The protection and display design plan covers Long kiln sites no. 1 and no. 5. In 2017, the team received an invitation from CLAB to provide a technical advice on the rammed earth building for its "The Innovative Lab of Architecture & Art " (ILAA) project at the Qiong Kiln Herritage Site Park.The entire building space contains a cafe for public events, a common area and two studios for an architect and artist. ILAA will use anti-seismic rammed-earth as a structural system of space rather than merely a visual decoration. It can be re-degraded into land after its end of life rather than becoming a construction waste. Please click hereto see the sharing of construction experience。 Collaborating Partner:CLAB @ Chengdu Work Progress

Jun 2017 - 1st Investigation trip The main purpose of the trip is to have a site visit, to meet the villagers and to discuss the construction design with the architects of CLAB. Meanwhile, soil was collected from the Park for analyst purpose.

Master Drawing:

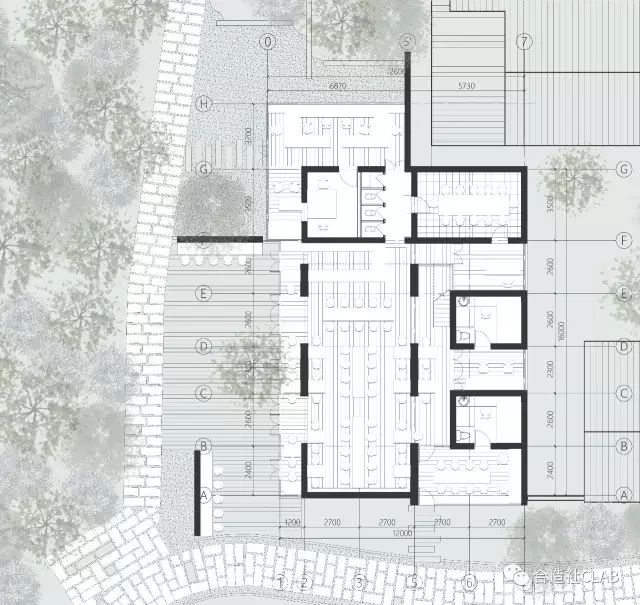

Floor Plan:

|

|